Mining

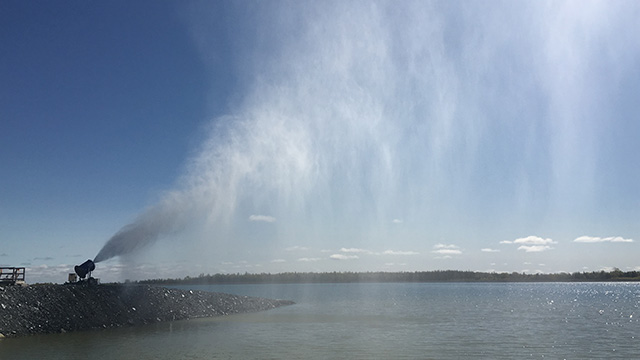

Mining operations require dust suppression and evaporation technology at various locations of the mine site. From drilling and blasting to crushing and material handling, HKD Blue technology is effective at controlling dust emissions throughout the process of the mine. Tailings water is one byproduct of the mining operation and HKD Blue machines are highly effective in evaporating the residual water.

Steel Production

Steel mill operations emit fugitive dust, exasperated by the handling of raw bulk materials such as Petroleum Coke, Iron Ore, and Manganese. The transfer of these materials between ships, rail cars, hoppers and loading areas, adds to the dust problem. HKD Blue machines are engineered to overcome these challenges, while also mitigating dust emissions from Slag dumping areas. The fugitive dust byproduct of the smelting process, when that material is dumped from the Pot Carriers, is significant and requires HKD Blue misting technology.

Metal Recycling

HKD Blue machines are used to control dust and smoke at metal recycling facilities across the United States. Scrap metal piles collect dirt, dust, and rust and when handled in large quantities by scrap grapples and loaders, dust emissions are significant. HKD Blue machines are also used at metal shredding plants (Hammer Mills) on the stockpiles during load out. Shredded iron that is left out to dry and rust is very dusty, particularly when transport is required betweeen trucks, rail cars, or vessels.

Metal recycling facilities also require smoke control. You’ll find that some sections of steel or metal components are too thick to be cut by a shear need to be cut and processed by torches. This generates harmful smoke emissions and HKD Blue atomized water technology mitigates the emissions and provides clean air and a safe working environment.

Port Facilities

HKD Blue units are used at port facilities for handling bulk products in large quantities. When a ship is at the port, cranes and loaders are running 24/7 to get the ship unloaded and the product heading to its destination. The more material being moved at once, the more dust is created, demanding HKD Blue equipment to suppress fugitive emissions. Some of the primary products handled that required dust suppression include Pet-Coke, Manganese, Coal, Fly Ash, Bauxite, Aggregates, Shredded Iron, Pig-iron, and iron-ore. The machine of choice for this type of facility is generally a Self-Contained option (V-400 GT). This allows them to pump water directly from the river.

Demolition & Construction

Demolition activities often create massive uncontrolled dust challenges as the contractor is often processing various materials for recycling, such as concrete, asphalt, steel, aluminum, and dirt.. Specialized demolition tools such as concrete pulverizers, shears, or grapples that dismantle the building create dust emissions in specific locations. The HKD Blue Geyser center nozzle is the perfect tool in this situation. Huge throw, oscillation, and a wide range of flows.

Environmental Remediation

Sites that were previously power generating stations, manufacturing plants, or industrial sites often have contaminated material or soil that must be remediated before the site can be reused. These sites are often called “Brownfields” and HKD Blue dust suppression is used to mitigate the emissions of contaminants during excavation activities.

Aggregates

Crushing, transporting, and handling aggregates creates extensive dust and HKD Blue machines are designed to mitigate it. Often, mist is sprayed on the “feedstock” or material that is going to be crushed into a finer product, to prevent over saturating on the conveyor belts and to mitigate dust during the impact of a crusher. Further downstream in the operation is “Stacking” the material into large stockpiles by conveyors. HKD Blue machines control aggregate dust through the performance and dependability of its machines.

Waste & Recycling

Waste Transfer stations handle municipal waste and debris from construction and demolition (C&D) activities. These facilities use cannons with lower flow rates to populate the air with a dust-fighting atomized mist, without saturating the material that needs to be handled or recycled. Elevated units are often most effective, as the mist stays suspended in the air longer, increasing its ability to fight dust.

Find a Dealer

Our versatile, powerful machines are specifically designed to solve your dust suppression, odor control, and evaporation needs. Learn more about how we can help with your next project using our efficient solutions.

Find a Dealer →