Controlling fugitive dust emissions from demolition work, bulk handling, concrete manufacturing, and scrap metal processing requires water based suppression strategies. As powerful water atomizing dust suppression machines replace traditional “hose in hand” methods; and companies scramble to adapt to shifting local and federal regulations; leading manufacturers of Dust Control Equipment like HKD Blue have introduced a range of automatic machines used by demolition crews, maritime operators, and scrap recycling facilities for fugitive dust control.

Table of Contents:

Introduction: What is fugitive dust control, and how can HKD Blue help?

What sites require atomized water suppression for fugitive dust control?

OSHA Table 1: jobs that require water based solutions

HKD Blue Dust control for demolition companies

HKD Blue Fugitive dust control for the maritime industry

HKD Blue Fire suppression at scrap recycling facilities

4 Innovative HKD Blue case studies for containing fugitive dust

How companies get OSHA compliant for respirable silica dust

HKD Blue leading dust suppression technology

What is Fugitive Dust Control, and How Can HKD Blue help?

Fugitive dust control can describe a number of a different strategies used on construction sites, bulk loading terminals, aggregate operations, and concrete facilities to control and contain particulate matter emissions.

A top OSHA regulation requires employees exposed to harmful fugitive dust to wear respiratory masks, but major demolition sites and loading and handling of hazardous bulk materials requires additional levels of protection.

Water-atomizing dust suppression technology such as the HKD Blue V-500 are a key element of fugitive dust control strategies for large scale operations. Federal and state regulators across North America (including OSHA) require water based methods to control fugitive dust when respirable levels of materials such as silica reach unsafe levels for workers.

Water based methods traditionally involved “hose in hand” strategies (both inefficient from a labour and environmental perspective) but industry leading manufacturers such as HKD Blue offer a range of powerful dust suppression machines specifically engineered to fit your site’s dynamic needs.

What sites require atomized water suppression for fugitive dust control?

© CEphoto, Uwe Aranas

Water atomizing dust suppression machines are most commonly used on major demolition jobs but changing regulations and cutting edge engineering is expanding the range of industries that are adopting the technology.

In addition to demolition crews, marine operators at dry bulk port terminals and major scrap yard operators have increasingly adopted atomized water suppression machines.

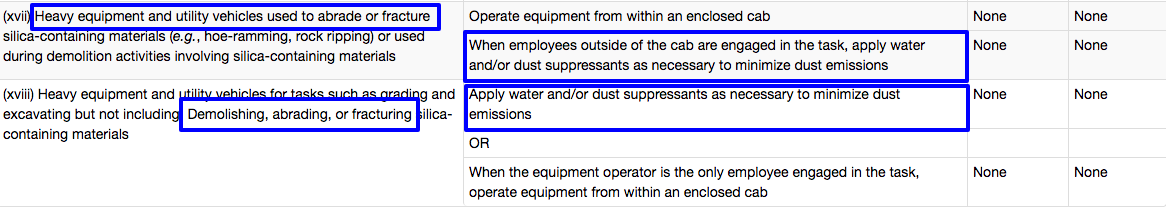

OSHA regulations in the U.S. require “equipment designed to deliver water spray or mist for dust suppression” for any operations involving heavy machines used to “abrade or fracture silica-containing materials.”

See OSHA Table 1 Below

The column on the left describes the types of work that require water based dust control methods. To view the entire table, click on the source link below:

Source: OSHA Website

OSHA recently expanded the range of companies required to adopt these measures to include any company with employees involved in the movement of dry bulk materials.

In addition to demolition crews, port terminal operators including stevedoring companies and longshoremen involved in the loading and unloading of bulk materials that produce fugitive dust must also introduce water atomizing dust suppression machines.

If atmospheric conditions cause respirable fugitive emissions levels to reach a set minimum standard, operators must shut down unless they are able to design and introduce specific control methods that include water atomized suppression machines.

Before you start your next job, contact HKD Blue to receive a free Dust Control Compliance Strategy.

HKD Blue V-500 Dust control for demolition companies

Major demolition projects require calculated dust suppression strategies. The fracturing and abrading of concrete, steel, aluminum, drywall, ceramics, and other construction materials creates dangerous and nuisance dust for crews and surrounding areas.

Traditional “Hose in Hand” methods waste labor resources on site and the water droplets produced by hoses are too large to effectively capture dust particles emitted from the demolition.

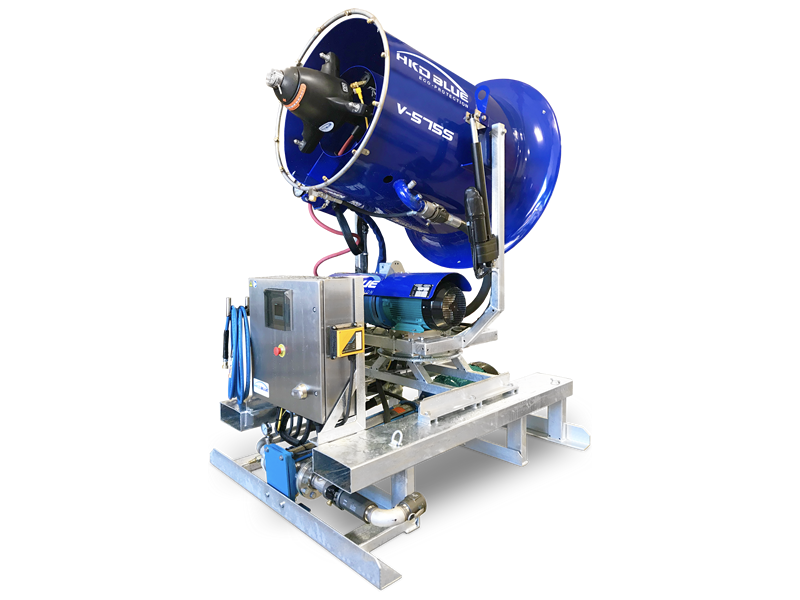

Industry leading machines such as the V-500GT are engineered specifically for demolition sites. HKD Blue’s dust control machines are powered by powerful 25 HP pumps capable of pressurizing atomized water mist across hundreds of thousands of square feet and with a maximum throw of 250ft.

Powerful water suppression nozzles can also be engineered to fit on the arm of a high-reach excavator, offering atomized water suppression directly at the source of emission.

HKD Blue Fugitive Dust Control for the Maritime Industry

All companies in Maritime Industry with employees who might be exposed to respirable crystalline silica are required to assess and implement water based suppression methods.

All companies in Maritime Industry with employees who might be exposed to respirable crystalline silica are required to assess and implement water based suppression methods.

Federal and local regulations apply to port terminal operators, shipping and bulk handling companies, stevedoring employers, bulk storage facilities among others.

When dry bulk materials such as coal, iron ore, manganese, clinker, scrap metal, and others are on and offloaded at port terminals across North America, atmospheric conditions can create fugitive dust emissions that must be corralled by responsible companies

Operators must also comply with state and local regulations specific to the zoning designations of each site. These regulations require dynamic, custom engineered solutions specific to the conditions of a specific terminal or single dry bulk loading job.

Operators use HKD Blue V-500 atomizing dust suppression machines as dry bulk materials are offloaded from vessels. The machines are mounted on a boom or fixed on steel towers.

In addition to variable spray patterns and distance, operators adjust the size of the water droplets ejected from the GEYSER nozzle depending on the fugitive emission pattern and consistency.

The “Wall of Water” projected by HKD Blue dust suppression machines catches and corrals fugitive dust and blocks its escape into the atmosphere.

These measures can be used in coordination with physical barriers and must be carefully designed. Despite active water based fugitive dust suppression methods, operators must monitor levels of respirable dust throughout the dry bulk handling and while the material is stored to await further shipment.

When maximum levels are hit, port operators must shut down and incur expensive delays.

HKD Blue Fire suppression and dust control at scrap recycling facilities

In recent years, scrap operators looking for industrial grade fire protection machines have turned to companies that provide fugitive dust emission control and environmental solutions primarily for demolition crews and dry bulk terminals.

Industry experts have noted a continuing trend in dangerous and costly fires at scrap yard facilities in the U.S. and around the world.

The National Fire Protection Association documents over 30,000 fire incidents at metal scrap recycling facilities every year with an estimated cost of over U.S. $1 billion in direct property damage. (Source)

Batteries, manganese, and other flammable materials located deep in scrap piles can smolder for hours before being discovered and extinguishing fires at scrap recycling facilities can take days.

Heavy operations and safety concerns at scrap yards limit maintenance teams with options when they must implement water suppression strategies amongst thousands of tons of recycled metals and heavy equipment used to move it.

Strategically placed HKD Blue V-500 water atomizing mist machines capable of dispersing water across large piles of potentially flammable materials are increasingly being used as a prevention solution to the fires.

The highest quality HKD Blue machines have pumping and nozzle capability offering up to 100 gallons per minute at 400 PSI (if needed) and provides remote control water flow capability allowing operators to rotate spray direction 330 degrees.

4 Case Studies of HKD Blue V-500 Units Controlling Dust In Various Industries

#1: High HKD Blue Machines Used to Control Dust During Major Highway Demolition

Highway construction in the city of Montreal is endless. Aging infrastructure has forced crews to completely rebuild major parts of the Turcot Interchange. Many of the 300,000 drivers who use the exchange may have noticed the sleek blue machines throwing atomized water mist over heavy excavator crews tearing sections of road away.

#2: Port of Quebec Uses Networked Instillation to Control Fugitive Dust

As evolving shipping technologies allows for larger cargo holds, shipping terminals are being forced to update their fugitive dust suppression strategies to provide coverage over increasing storage areas and larger freighter holds. At the Port of the Quebec, stevedoring companies operate a network of tower mounted water atomizing suppression machines via a central control room.

#3 Massive Aerospace Facility Demolition Requires Powerful Water Atomizing Technology

Long before one of the world’s leading manufacturers in the military and commercial aerospace industries completed its state of the art production facility in upstate New York, demolition crews used powerful water atomizing dust suppression machines to control silica dust emissions as they dismantled the company’s existing 700,000 square foot complex.

#4: Controlling Emissions From Dangerous Offloads at Port of Chicago

It doesn’t happen often, but when companies maneuver bulk manganese loads at the Port of Chicago, they cannot afford to take any chances. With lives potentially on the line, a recent offload used an arrangement of shipping containers and powerful water atomizing cannons to contain and corral the dangerous material’s fugitive emissions.

How Companies Get OSHA Compliant for Respirable Silica Dust

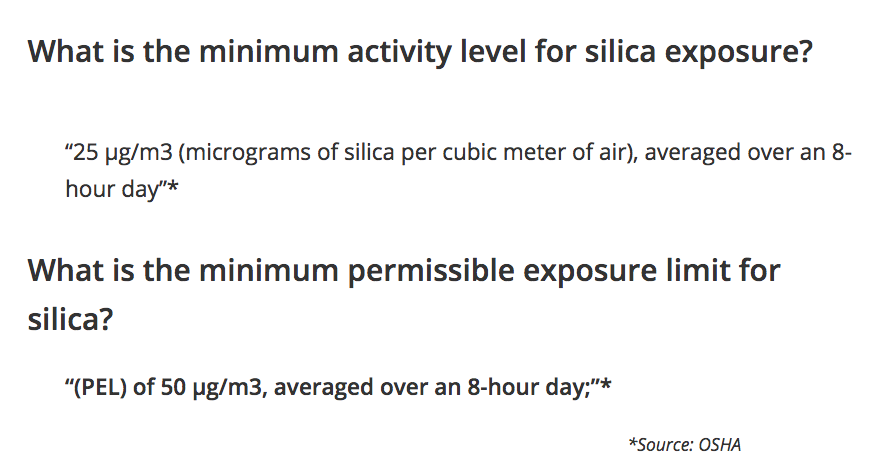

If materials containing silica are fractured or abraded, a respirable dust is emitted that can cause serious, irreversible health complications if inhaled.

Federal authorities recently introduced new silica standards and experts believe OSHA regulators are preparing for a busy season enforcing the new codes.

Under the new regulations, any company where silica dust is present – milling operators, scrap yards, paving mills, glass manufacturing companies, dry bulk handlers transport operators, and shipyard employers – can be now be fined.

Depending on what your job entails, you will need to implement one or a number of dust control methods.

To read a step by step guide on how to get OSHA compliant, click here.

Not sure if you need water based dust control machines?

Tell HKD Blue about your site and the company will send you a free Dust Control Compliance Strategy.

Industry Leading Dust Suppression Technology

Dust control requires a dynamic solution

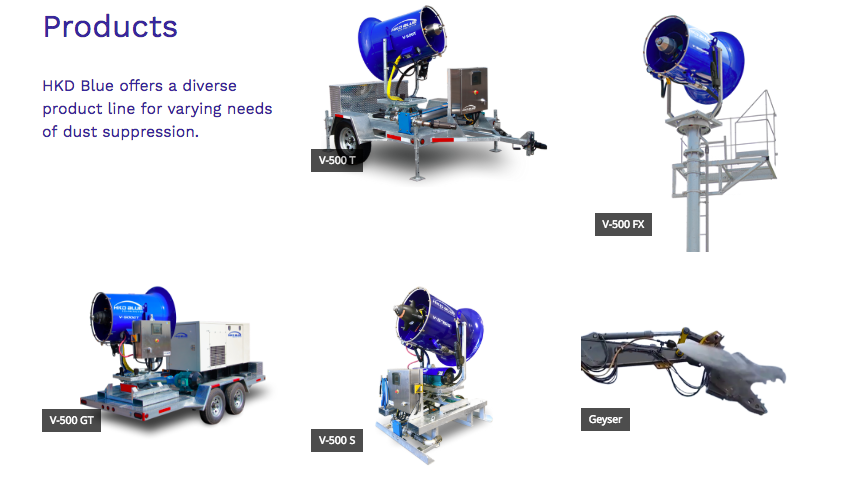

No demolition site or port terminal is alike. Born from its parent company HKD Snowmakers, HKD Blue provides a range of high quality water atomizing mist machines engineered by hand at the company’s manufacturing facility in Quebec.

All of HKD Blue’s machines are engineered with V-Flow Technology providing the ability to improve water spray accuracy and efficiency.

Spray pattern, water flow, droplet size and range are all calibrated to match a site’s dynamic conditions. Operators use remote control technology.

For larger, fixed operations, HKD Blue’s V-Flow 500 FX units can be mounted on fixed tours with multi unit instillations controlled by a centralized computer network.

With an engineered center of gravity, HKD Blue’s V-500S skid units are crane accessible, or can be mounted on DOT certified trailers.

Not sure if you need one of our machines?Check out our dust control products page or tell us about your site and receive a Free Dust Control Compliance Strategy.